Compressed air applications in Marine

Air Lubrication

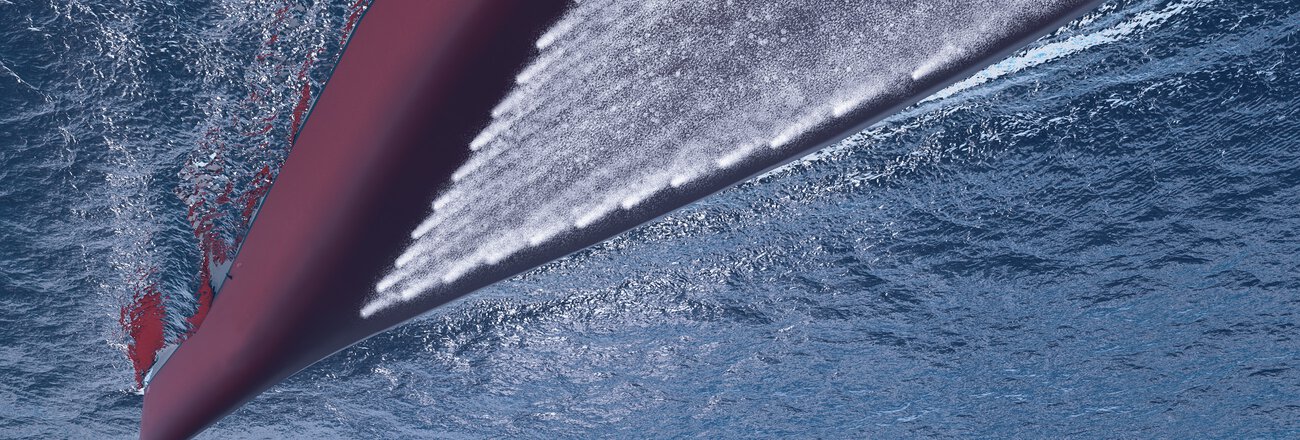

Air lubrication is an innovative energy efficiency technology that utilises low-pressure air to reduce a ship’s frictional resistance - the drag or ‘stickiness’ caused by the seawater rubbing against the hull as the ship moves through it. Although being an old technology, it has been further developed in recent times to enhance vessel efficiency and reduce environmental impact, helping ship owners meet stringent international regulations.

Low-pressure air is injected through nozzles or air release units (ARU) that are strategically located along the flat bottom of a wetted hull surface. These nozzles or ARUs then release microbubbles into the boundary layer along the hull, creating a large continuous and uniform ‘air carpet’. The laminar flow in this boundary layer of air and seawater mixture significantly reduces the frictional resistance. Less frictional resistance means less thrust - or power - is required to overcome it, translating into reduced fuel consumption and CO₂ emissions.

The current air lubrication systems have the potential to create net fuel savings of up to 10% and reduce the carbon footprint of the vessel, while also potentially reducing hull fouling. Besides, studies have also shown that it can reduce underwater radiated noise (URN), which has benefits for the marine life as well as potentially creating a quieter onboard environment.

There are a number of possible air lubrication methods, however the microbubble method is one of the most typical thanks to its ability to create a stable ‘air carpet’ and to deliver effective friction reduction. These systems may require compressed air or low-pressure air to operate depending on a number of factors. To blow microbubbles under the hull, the corresponding static pressure of 0.5 to 2 bar has to be overcome. In combination with the dynamic pressure, which depends on the air speed and the pipe diameters and lengths, around 1 to 2.5 bar must be applied. In addition, the size and design of the vessel will also impact the compressed air requirement.

Achieving true energy and emissions savings with air lubrication hinges entirely on the efficiency of the accompanying compressed air system. If the energy consumed by the compressed air system to operate the air lubrication system (ALS) is excessive, the net savings can be diminished. Therefore, the net gain in reduced fuel and emissions must be higher than the power required to operate the compressed air system. A key aspect of this efficiency is the compressed air system’s ability to operate with a low outlet temperature, as this indicates less energy is being wasted as heat during the compression process. Opting for a reliable and energy-efficient compressed air technology that is correctly sized to meet the specific compressed air demands of the ALS’s operating profile, and is correctly controlled and maintained, will all impact its overall efficiency and thereby the final net gains a ship operator can realise from utilising air lubrication to reduce frictional resistance.

KAESER solutions for Air Lubrication in Marine

KAESER rotary screw blowers present the ideal solution to energy-efficiently meet the low-pressure air requirements of air lubrication systems. Featuring the world-renowned SIGMA PROFILE rotors, these highly efficient blowers ensure maximum air delivery whilst keeping power consumption to an absolute minimum. Savings of up to 35% are possible with KAESER rotary screw blowers in comparison to conventional blower systems.

Thanks to an intelligently designed and exceptionally compact layout, KAESER rotary screw blowers are perfectly at home on a vessel where space is at a premium, offering ease of installation and allowing all maintenance work to be performed conveniently from the front. These “plug-and-play” complete solutions are accepted and approved by all notable vessel classification societies, validating their durability and reliability under the demanding conditions of the high seas.

FAQs

The relevant pressure will depend on the draught of the ship and the air lubrication system itself. The deeper the hull sits in the water, the higher the pressure will need to be to overcome the hydrostatic pressure of the seawater. Ultimately it will depend on the specific pressure and flow rate required for your vessel’s unique operating profile.

Let our marine compressed air experts assist you with your air lubrication system blower requirements. Contact KAESER Marine today!

- Efficiency: An inefficient blower consumes excessive power, which can negate a vessel's fuel savings. For maximum efficiency, the blower itself needs to operate as energy-efficiently as possible. This is a core benefit of the KAESER rotary screw blower range, which allows savings of up to 35% in comparison to conventional blower systems. This high efficiency is achieved through an advanced design featuring internal compression, which results in a low outlet temperature—a crucial factor for both efficiency and system longevity.

- Reliability: The demanding marine environment requires a robust and durable design that can withstand vibrations, temperature fluctuations, and seawater. The KAESER rotary screw blower range as an example, is built to meet these rigorous standards and is certified by all major marine classification societies.

- Practicality: With only limited space onboard, a blower should have a compact footprint and be easy to install and maintain, simplifying upkeep and reducing costly downtime. KAESER rotary screw blowers are designed with these practicalities in mind, making them an ideal solution for shipboard applications. Whatsmore, KAESER Marine Service is only a moment away and a KAESER service specialist can be waiting at your next port of call to tend to your service requirements.