How KAESER can energy efficiently meet the compressed air requirements of Wastewater Treatment Plants

Compressed air is essential to many processes that take place in a wastewater treatment plant (WWTP). It’s also one of the largest energy consumers at a WWTP, and as more operators seek to minimise their carbon footprint and reduce their operating costs, choosing intuitive and energy efficient compressed air equipment has never been so important. In this blog post we take a closer look at the typical compressed air applications of a municipal WWTP in an industrialised country, and discuss how KAESER’s advanced and intelligent compressed air solutions can energy efficiently meet these requirements - optimising the associated energy consumption and carbon footprint.

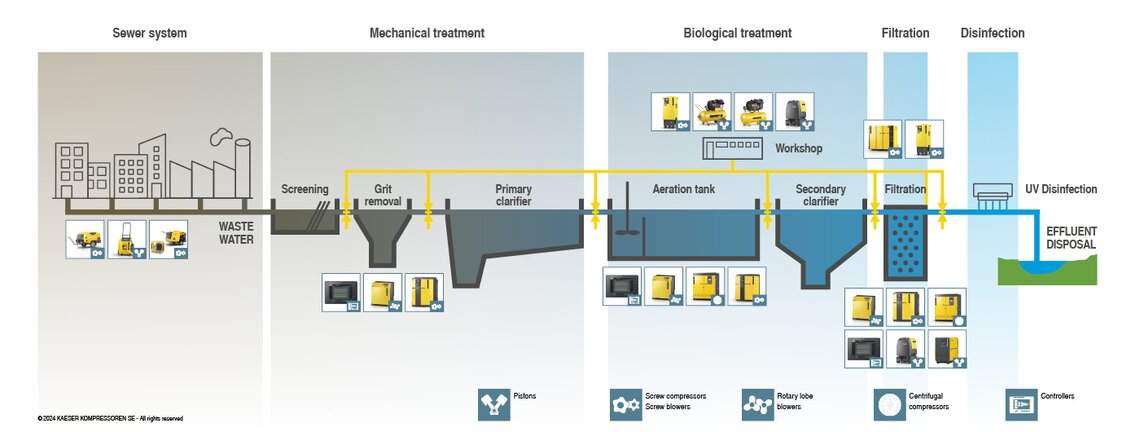

Typical compressed air applications in a WWTP

Intelligent KAESER compressed air solutions in use at a municipal Wastewater Treatment Plant

Download

Process diagram in detail

Compressed air in a WWTP

Sewer rehabilitation

Compressed air is used extensively in trenchless sewer rehabilitation, from inflating sewer sealing cushions and powering pneumatic milling machines used to remove tree roots, to feeding and pressing inliner into position in the pipes, as well as cooling the UV lamps used to harden lining material.

For such applications, a compact, lightweight and portable compressor that delivers a reliable, efficient and high quality supply of compressed air is required. And, depending on the location of the sewer rehabilitation work, the compressor may also need to be able to operate in strict low emission and noise protection zones.

Designed to deliver more compressed air with fewer emissions, the extensive MOBILAIR range of portable compressors and accessories encompasses many options to reliably, efficiently and effortlessly meet the high air quality requirements of sewer rehabilitation.

KAESER solutions:

Grit removal

Reliable and efficient blowers are required when an aerated grit removal system is being employed. Influent passes through the chamber at a reduced flow so rough waste, such as sand and stones, can be separated out by sedimentation. Sedimentation is enhanced by using blowers to aerate the chamber to induce a spiral flow. The small air bubbles additionally support the separated fat and oils to float to the surface, which are then continuously mechanically removed. Ineffective grit removal, caused by an air volume that is too high or insufficient, can cause abrasion, contributing to equipment wear as well as clogging further downstream. It can ultimately hinder the effectiveness of the subsequent treatment processes. Optimum aerated grit removal therefore relies on the blower precisely meeting the compressed air demand and pressure required. KAESER works with its customers to understand the demands of their specific operating conditions, in order to present a reliable blower solution for optimum grit removal and economical operation.

KAESER solutions:

Aeration systems for biological treatment

Low-pressure air plays a vital role in aeration systems used for biological treatment, where blowers typically generate streams of fine air bubbles which are injected through the influent, in order to oxygenate the wastewater required for bacteria to breakdown the organic matter present.

The optimum blower solution for any given aeration system will depend on a number of factors including; the location and size of the plant, as well as the biological treatment method and technology being employed such as; activated sludge, MBR, MBBR and so on.

An efficient and reliable supply of compressed air is not only critical to the success of the biological process, but it will also impact the overall energy consumption of the aeration blowers. KAESER works closely with its customers to deliver innovative and turnkey Water 4.0 blower stations, for optimum biological results, maximum efficiency and low energy consumption.

KAESER solutions:

Filter backwashing

When wastewater is required to meet defined quality standards or environmental regulations relating to reuse or discharge, it is often filtered following completion of the biological treatment.

To maintain the functionality of support systems, filters and the filtration process, and to ensure the quality of the filtered water, continuous or semi-continuous filter backwashing is frequently employed.

This involves adjusting the water flow to backwash the filters, while air is used to blow the accumulated debris and particles from the filter outlet to the filter inlet, where they are released.

Depending on the technology used for backwashing the filters, a higher or lower air pressure may be required. Rotary lobe blowers from KAESER are ideal for low-pressure filter backwashing. They are designed for maximum efficiency, dependability and durability with minimum maintenance requirement, and ensure lowest possible life-cycle costs.

When it comes to high-pressure filter backwashing, KAESER’s oil-free reciprocating compressors from the i.Comp and AIRBOX series are the ideal solution, since they offer a multitude of options for fulfilling the requirements of this application.

KAESER solutions:

Pneumatic control

The entire operating process at a treatment plant, e.g. adjustment of valves, gates and flaps, is often controlled using pneumatic actuators. This enables precise and reliable control even under harsh conditions (e.g. in corrosive environments or low ambient temperatures). In some cases, the compressed air network is also used for supplying air-operated pumps and for sludge drying applications. KAESER offers an extensive selection of rotary screw compressors and compressed air treatment components to meet a wide variety of requirements in relation to pneumatic control at a wastewater treatment plant. The range begins with the compact AIRCENTER – the complete system comprising a highly efficient rotary screw compressor with an integrated refrigeration dryer and air receiver. The refrigeration dryer, together with an optional microfilter, ensures clean, dry air that can be used for reliable operation of pneumatic valves. For larger treatment plants requiring a dedicated compressed air supply, KAESER can provide a complete, future-proof compressed air station designed for maximum efficiency.

KAESER solutions:

Workshop air

In a treatment plant workshop, a dependable supply of quality compressed air is frequently required for a variety of tasks, such as operating air tools or cleaning workpieces. For workshops that do not require constant high volumes of compressed air, reciprocating compressors from KAESER are the perfect choice. They are available in mobile (CLASSIC/PREMIUM series) or stationary (KCT/AIRBOX series) configurations. For larger workshops with constant compressed air demand, a rotary screw compressor may be the optimal solution. Compact KAESER AIRCENTER models provide a complete compressed air system comprising a highly efficient rotary screw compressor with an integrated refrigeration dryer and air receiver. Thanks to the optional SIGMA CONTROL 2 controller, they can also be integrated into the treatment plant’s central control system. The AIRCENTER combines exceptional efficiency and cost-effective performance with super-quiet compressed air generation, treatment and storage, making it ideal for installation directly at the point of use. Alternatively, perhaps the SXC series would be a good choice. Here we have a dependable, standard compressor package that also includes a refrigeration dryer and air receiver, all encompassed inside a durable polyethylene housing for protection.