From application to solution: Construction site compressed air applications, requirements and KAESER solutions

From driving pneumatic tools to streamlining fibre optic cable installation, compressed air is a vital utility on construction sites. These environments demand portable compressors that deliver consistent performance, no matter the conditions. In this blog post we explore key applications, their compressed air requirements, and how KAESER’s versatile range of portable compressors meet them with efficiency, reliability, and engineering that stands the test of time.

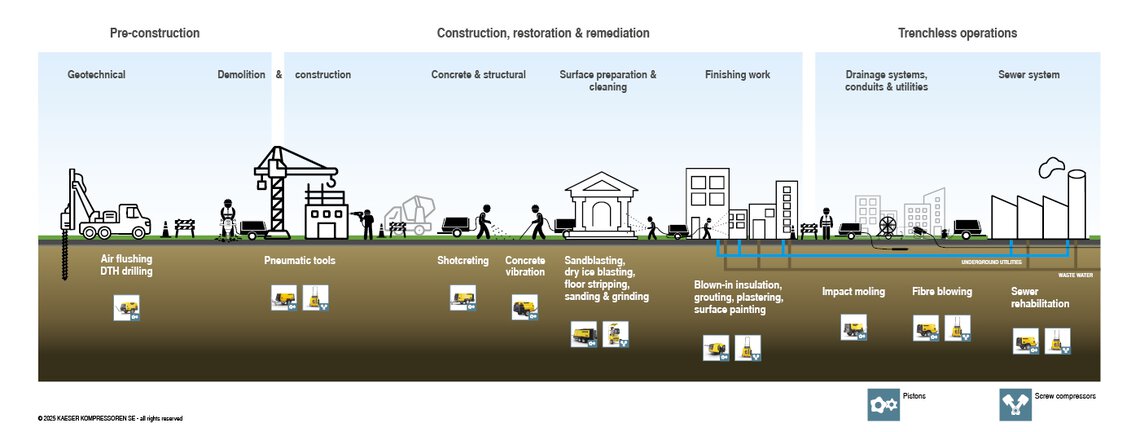

Typical compressed air applications in construction

KAESER compressed air solutions in use on the construction site

Download

Process diagram in detail

Compressed air on the construction site

Geotechnical

Pre-construction of major structures typically starts with a geotechnical investigation to assess the strata. This often involves geotechnical drilling to gain access to subsurface soil and rock so it can be analysed.

A number of geotechnical drilling methods require air flushing, where high-pressure compressed air is circulated down a borehole and back up to the surface in order to transport the cuttings produced by the drill bit during drilling operations.

When the down-the-hole (DTH) drilling method is employed, compressed air will also often be required to operate the drill, delivering the percussive energy to the hammer required to break the rock.

A reliable supply of compressed air is essential for geotechnical drilling to ensure that the drill bit can work continuously to advance the borehole, maintaining optimum drilling conditions.

Developed for efficiency and reliability in demanding environments

MOBILAIR portable compressors are built to handle the continuous demands of geotechnical drilling with robust, reliable performance - even in the toughest conditions. Thanks to KAESER's energy-efficient SIGMA PROFILE rotors, they deliver exceptional compressed air output with reduced fuel consumption. A wide range of equipment and compressed air treatment components ensures the required air quality is always met. Stationary versions are also available, perfect for mounting on drill rigs.

Find out more about KAESER solutions for geotechnical:

Demolition & construction

Many demolition and construction tasks rely on pneumatic tools which require a dependable supply of compressed air to operate effectively. For optimal performance and safety, the compressor’s capacity should be matched to the requirements of the pneumatic tool, as inconsistent air pressure or a sudden drop in air supply could for example lead to a pneumatic tool stalling or losing its torque.

Aside from being robust and able to withstand harsh environments and conditions, another important consideration is compressed air quality. Poor compressed air quality can lead to a number of problems such as premature wear of pneumatic tools and compromised performance. Compressed air treatment is therefore often required.

Typical pneumatic tools:

- Breakers

- Hammer drills

- Impact wrenches

- Nailers

- Screwdrivers

- Chipping hammers

- Drills

Power you can count on.

KAESER portable compressors are built for the toughest jobs. Durable and dependable, they deliver the consistent power pneumatic tools need to perform efficiently and without compromise.

Find out more about KAESER solutions for demolition and construction:

Concrete & structural work

Compressed air is often required in the placing and finishing stages of laying concrete where it plays a pivotal role in achieving good compaction. From shotcreting to concrete vibration, the compressed air supply must reliably meet the pressure and airflow required of the equipment, while delivering cool and condensate-free compressed air, for optimum results. And, depending on the application, technically oil-free air may be essential.

Versatility meets performance

With a wide range of equipment and compressed air treatment options, MOBILAIR portable compressors are ready for whatever the job demands. They deliver outstanding power, flexibility and rock-solid reliability - every time.

Find out more about KAESER solutions for concrete & structural work:

Surface preparation & cleaning

Cleaning graffiti off a wall, removing rust from a bridge, stripping floors, or even restoring surfaces in a historical building - there are many surface preparation and cleaning tasks in the construction sector that require compressed air to effectively get the job done. While the compressed air requirements may vary by application, in all cases the compressed air supply will be critical to operational efficiency, achieving consistent results, and equipment longevity.

Reliable compressed air for every surface

KAESER portable compressors deliver a steady, dependable supply of compressed air - perfectly suited for both outdoor and indoor surface preparation and cleaning. With a full range of compressed air treatment options available, achieving the right air quality for the job is simple and seamless.

Find out more about KAESER solutions for surface preparation & cleaning:

Finishing work

There are many finishing jobs in the construction sector where pneumatically powered equipment is often utilised for speed and efficiency, such as surface painting, plastering shells walls and installing blown-in insulation. Whether it be for hopper guns used in plaster spraying or conventional spray guns used in surface painting, for optimal performance, maximum efficiency, and consistently high-quality results, the compressed air supply always needs to meet, and dependably maintain the required air pressure and airflow of the pneumatic equipment.

Ready for the finish, built for the long haul

Simple to operate, efficient, and built to perform, KAESER’s portable compressors are designed for continuous use on demanding construction sites. Available in a wide range of sizes, they’re perfectly suited for the full spectrum of finishing work applications.

Find out more about KAESER solutions for finishing work:

Trenchless operations

Many trenchless technologies require compressed air in repairing, replacing and installing underground utilities. For maximum efficiency, reliability and longevity of the associated trenchless equipment, cool and condensate-free compressed air is almost always recommended. High-quality compressed air will also be essential for some of these applications. Of course precisely meeting the pressure and flow requirements of the application is also essential and will effect the efficiency, and performance of a compressed air system for each specific trenchless technology application.

Precision compressed air for trenchless work

With a broad selection of sizes, pressure levels, and configuration options, KAESER portable compressors deliver the precise air flow, pressure, and quality trenchless technology demands - efficiently and reliably.

Find out more about KAESER solutions for trenchless operations: