Compressed air applications in Aquaculture

Sea Pen Aeration (SPA)

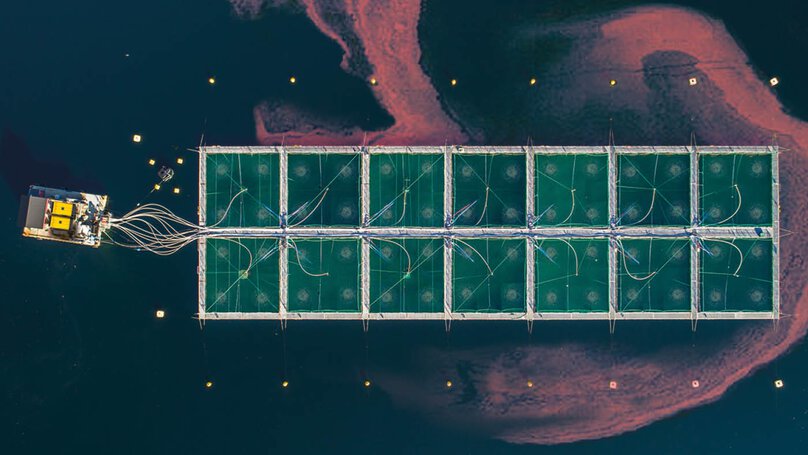

Sea Pen Aeration (SPA) is becoming increasingly important to coastal aquaculture farms to combat two major challenges; oxygen deficiency and harmful algae, both of which can compromise fish health. There are many factors which can lead to low oxygen levels in near shore aquaculture farms. High temperatures are a key driver, as are algae blooms that consume oxygen during the night. When such algae blooms die off, the extreme decomposing biomass also consumes oxygen. In addition, seasonal conditions like thermal stratification also play a role. Common in static water and typical in warmer months in temperate regions, thermal stratification sees the temperature of a water column split into distinct layers. The top layers of water typically become warmer while the deeper layers remain cooler. This inhibits the natural process of oxygen circulating throughout the water column. It also creates favourable conditions for algae to bloom, as well as leading to increased activity and reproduction of harmful organisms like sea lice. The combination of these factors can lead to a multitude of stressors that increase feed conversion ratios, and in the worst case scenario, can cause increased mortalities or susceptibility to diseases.

SPA utilises compressed air to improve oxygen levels in the water in order to create and maintain optimum conditions critical for fish health. Compressed air is blown into a net pen through diffusers, which release small air bubbles that rise to the surface of the water. A gas exchange then takes place between the water and the gases in the bubbles, increasing the oxygen level in the water. It also creates an artificial upwelling, which forces cold oxygen-rich water from the depths to rise up into the pens. Improving oxygen availability allows fish to thrive and survive. It allows them to better digest feed, reducing feed waste and improving the feed conversion ratio (FCR). This can have a positive impact on production costs - a significant operating expense (OpEx) in aquaculture.

The artificial upwelling additionally forces the water at the surface of the net pens to flow outwards. This prevents algae and other harmful organisms that occur in the top layer of the sea - like the planktonic copepodite stages of sea lice - from entering the net pens with inflowing water. This can save livestock and is a mandatory measure in some countries.

To maintain optimum conditions, the SPA system requires a reliable supply of high-quality compressed air. Any system failure could lead to hypoxic conditions and make the net pens vulnerable to harmful organisms, potentially resulting in mass fish mortalities.

KAESER Solutions for Sea Pen Aeration (SPA)

KAESER has developed specialised aquaculture-adapted, low-pressure compressed air solutions that energy-efficiently meet the high-quality compressed air requirements of Sea Pen Aeration (SPA). These robust compressed air solutions reliably deliver the clean compressed air that SPA systems demand, in order to create and maintain optimal upwelling.

KAESER solutions for SPA include:

MOBILAIR M 450LP low-pressure portable compressor

Reduce fuel consumption and lower CO2 emissionsThe MOBILAIR M 450LP from KAESER is a low-pressure version of the M 450 portable screw compressor. It has been specifically adapted with aquaculture applications like SPA in mind, offering an extremely fuel-efficient and robust solution that is perfectly suited to meet the harsh operating conditions of aquaculture.

With flow rates from 22 to 44 m³/min (800 to 1500 cfm), the M 450LP is the most versatile compressor on the market. The compressed air output can be precisely controlled by air demand (in cfm or m³/min), where the compressor keeps the volume constant within the set pressure limits. This means in case someone closes a valve and the pressure goes up and exceeds the set limit, the volume flow will be reduced. Alternatively, the compressor can be set on the standard pressure control where it will target a certain pressure and adjust the volume accordingly. The pressure range of the M 450LP ranges between 1 and 14 bar(g) (14.5 to 200 PSI).

The M 450LP can also be used as a fully autonomous compressed air station. It can be fitted with a 10 kVA generator which is capable of operating a refrigeration dryer - ideal when dry compressed air is required for active carbon filters, in order to generate high quality compressed air according to ISO 8573-1:2010 [1:4:1].

Low-pressure electric stationary compressors

Reduce energy consumption and lower CO2 emissionsKAESER’s stationary range of low-pressure electric rotary screw compressors are perfectly suited for pressures between 3.5 and 5 bar(g), and for farms where either shore power or enough generator capacity is available. The volume flow ranges from 4.7 to 86 m³/min. KAESER also offers a comprehensive range of compressed air treatment components such as filters and compressed air dryers.

Both of these options only compress the air to the pressure that is needed to overcome the hydrostatic pressure, as well as the losses of the pipe network.

As every 1 bar(g) of overcompression increases the energy demand by 7%, savings of up to 30% are possible with both KAESER’s low-pressure diesel portable compressor, and low-pressure electric stationary compressors.

FAQs

There are generally three different types of harmful algae.

The first type causes harm by depleting the oxygen in the pen, therefore causing hypoxia. Sea Pen Aeration systems work very well against mitigating this type of algae.

The second type of algae causes harm through toxins. It is important to ensure the aeration system operates at the right pressure, as an overpressurised aeration system can cause the cells to break, releasing even more toxins.

Finally the third harmful algae type causes structural damage. These algae mainly harm gill structures of fish. The aeration system must be carefully used to ensure these fragile algae don’t break up, which could lead to even more harm to the gills.