Compressed air applications in Aquaculture

Pneumatic Feeding

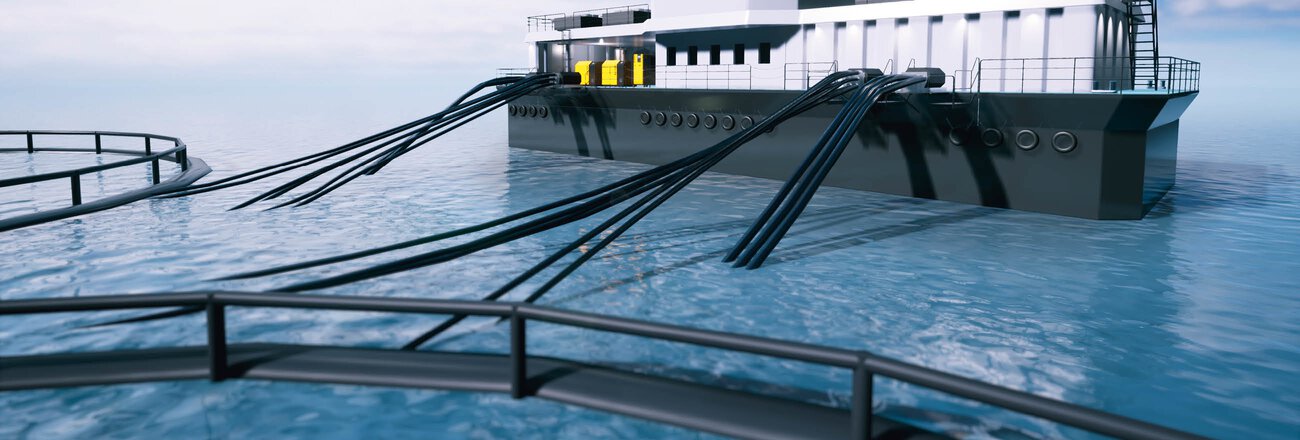

From the early life stages of fish through to the final grow-out phase, pneumatic feeding systems are widely used in modern fish farming to efficiently and gently transport pellet feed from silos into net pens.

Where the pneumatic feeding system is required to transport micron pellet feed to fish in the early stages of life, the dense phase pneumatic conveying method is typically employed. This requires compressed air at low-velocities and high-pressures to convey feed with a diameter of < 0.5 mm.

As fish grow so does the pellet feed size. Pneumatic feeding systems used to transport small and standard sized pellet feed (> 0.5 mm diameter) therefore employ the dilute phase pneumatic conveying method. This requires a reliable supply of high-velocity and low-pressure air. The demand for feed can surge when harvest nears and fish biomass increases. A reliable supply of low-pressure air becomes even more crucial to ensure the efficient and even distribution of feed, in order to maximise feed efficiency, reduce competition among fish, and promote uniform fish growth. For reliable and long-lasting performance of a pneumatic feeding system, the low-pressure air supply must also be high-quality.

As feed is the largest operational expense (OpEx) in aquaculture, the efficiency and reliability of the pneumatic feeding system - including the low-pressure air or compressed air supply - is vital, contributing to the optimisation of feed utilisation, preserving feed quality, supporting fish growth, and boosting overall farm productivity.

KAESER Solutions for Pneumatic Feeding Systems

KAESER blowers are trusted to reliably and efficiently supply the high-quality, low-pressure air required to pneumatically transport feed into net pens. KAESER has two different design concepts that effectively meet the needs of these pneumatic feeding systems; OMEGA rotary lobe blowers and SIGMA rotary screw blowers.

The COMPACT series CB 131 C rotary lobe blower has been specifically developed to meet the requirements of automated feeding systems in aquaculture. This three-lobe rotary lobe blower features the special OMEGA Profile, which guarantees high levels of energy efficiency. Designed and constructed for efficiency, reliability and durability, all COMPACT series rotary lobe blowers from KAESER, require minimal maintenance and service requirements, making them particularly suited to remote aquaculture locations, while assuring lowest possible life cycle costs.

There are a number of factors that should be carefully considered when choosing the right blower for a pneumatic feeding system. KAESER works closely with its partners and aquaculture OEMs to design and deliver highly reliable blower systems that efficiently meet the low-pressure air requirements of pneumatic feeding systems. With thousands of blowers being used with pneumatic feeding systems worldwide - some operating at sea since 2000 - KAESER is a market leader in this field.

KAESER also manufactures an extensive range of rotary screw compressors and compressed air treatment components that are ideally suited to meeting the high-quality compressed air requirements of pneumatic feeding systems used to transport micron pellets.

FAQs

It is not advisable to design your own feeding system due to the complexities involved in correctly conveying feed. This requires extensive knowledge and expertise to ensure the feeding system operates efficiently and without breaking or degrading pellet quality. Of course there may be some initial cost savings gained by designing your own feeding system, however as the largest operational expense, these savings would be quickly outweighed by any losses incurred from damaged or degraded feed.

It pays to invest in a professionally designed system to ensure its suitability to your specific site requirements.

KAESER works with its partners and aquaculture OEMs, to design and deliver tailored blower system solutions that meet the specific low-pressure air requirements of each pneumatic feeding system, for optimal performance and efficiency.

The reliability of every KAESER blower is the result of rigorous development and precision manufacturing.

As with all KAESER products, COMPACT blowers for example, are designed to provide maximum reliability. Every airend and blower block is meticulously built in accordance with KAESER’s renowned quality standards by highly skilled workers at the factories in Germany. Using various sensors, the optional internal SIGMA CONTROL blower controller monitors and controls all relevant parameters to provide reliable and efficient operation at all times. Optional remote monitoring and control further contributes to optimised blower availability.

There are a number of factors which will impact the necessary maintenance on a blower such as; the type of blower technology being employed, the quality of the blower and its suitability to the environment within which it will operate. The system design, the prevailing operating conditions, and workload additionally impact the required maintenance.

All KAESER blowers are meticulously designed and constructed with minimal maintenance and service costs in mind, contributing to lowest possible life cycle costs.

Take for example the COMPACT rotary lobe blower packages, they have been designed for ease of maintenance, allowing all work to be performed from the front end of these units, which allows them to be placed side by side.

All KAESER rotary lobe blowers feature precisely machine timed gears, highly durable roller bearings, and precision-balanced rotors, which all contribute to a long service life and low maintenance costs. This robust construction ensures a long service life and low maintenance requirements.

Of course even the highest-quality blowers require maintenance. KAESER’s worldwide service network and advanced spare parts logistics ensures continuous blower air availability across the globe.