Compressed air applications in Aquaculture

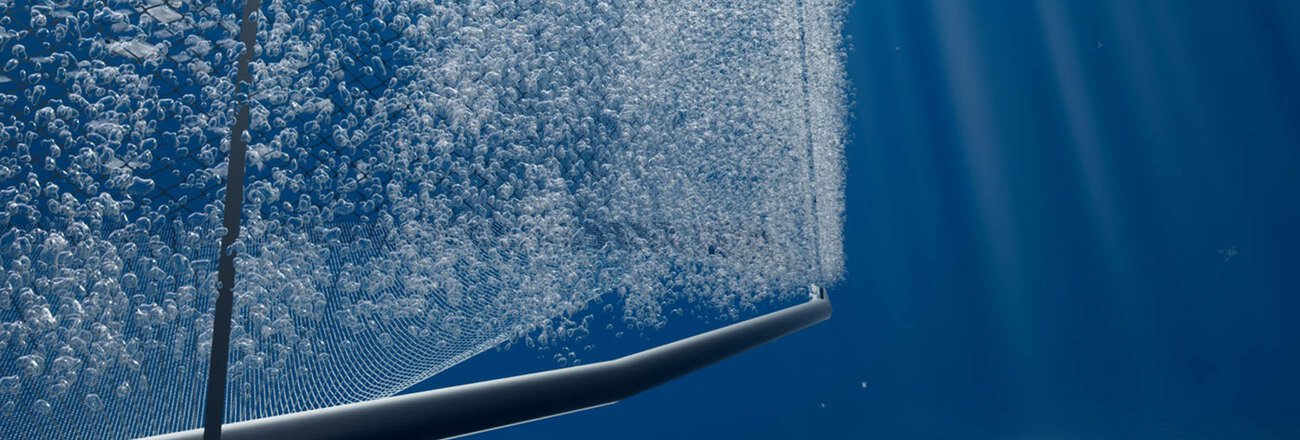

Aquaculture bubble curtains

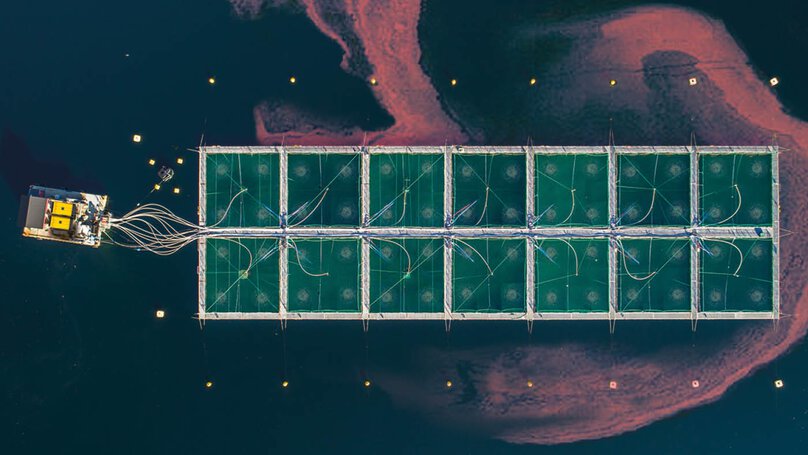

Bubble curtains are used in sea-based aquaculture to mitigate environmental threats to net pens, such as jellyfish and algae blooms. Bubble curtain systems have been found to be a simple, yet effective method of preventing such threats from adversely affecting the fish within the net pens.

A bubble curtain typically consists of a diffuser hose which is arranged in a ring around a farm at its lowest point. When a threat is detected, a steady flow of compressed air is pumped through the diffuser hose, releasing small, uniform air bubbles. As these air bubbles rise through the water, they create a continuous physical barrier (curtain), preventing jellyfish and algae blooms which are drifting with the current, from entering the net pens. The ocean current then drives the threat alongside the bubble curtain until it passes the farm.

To operate effectively, bubble curtains require a dependable supply of compressed air. For optimal performance, as well as to ensure equipment longevity, the compressed air system should also be designed to meet the specific site conditions of a net pen farm, taking into account the prevailing oceanic conditions.

Bubble curtains can have high operating demands, requiring a compressed air system that can operate for an extended period of time and run 24/7. For optimal mitigation results, as well as for energy- and operational- efficiency, a bubble curtain needs the right volumetric flow rate of low-pressure air. Here, the selection of energy-efficient compressed air equipment that has been specifically designed with these requirements in mind, can have a large impact on the associated fuel or energy consumption and CO2 emissions.

Bubble curtains can be a very effective protection measure against planktonic threats to fish. Nevertheless, it is only an adequate mitigation measure, if it’s deployed correctly and according to site conditions. Working with one of the expert companies that provide these products and services is therefore always highly advisable.

KAESER Solutions for Aquaculture Bubble Curtains

For over two decades, KAESER has delivered robust and efficient compressed air systems to the aquaculture industry that are tailored to meet the requirements of bubble curtains. Designed to withstand harsh aquaculture conditions, KAESER compressed air solutions are reliable and energy-efficient, ensuring maximum availability.

KAESER’s stationary rotary screw compressors and MOBILAIR portable compressors are ideal for this application. These durable and high-performing compressors, dependably and efficiently deliver the constant pressure that bubble curtains require over extended periods.

KAESER also offers a comprehensive range of compressed air dryers - an important addition in some locations in order to maintain reliable operation and protect equipment from premature wear caused by certain oceanic conditions.

At KAESER, we recognise that each aquaculture operation has unique compressed air needs. That’s why we work closely with our partners and customers to design and deliver tailored compressed air system solutions that meet the requirements of each bubble curtain, ensuring reliable performance while minimising operational costs and CO2 emissions.

FAQs

Yes, KAESER offers two energy-efficient solutions for this application:

- Low-pressure electric stationary compressors: KAESER’s stationary range of low-pressure electric rotary screw compressors are perfectly suited for pressures between 3.5 and 5 bar(g), and for farms where either shore power or enough generator capacity is available. The volume flow ranges from 4.7 to 86 m³/min.

- Low-pressure diesel portable compressor: the MOBILAIR M 450LP low-pressure portable compressor, with pressures ranging from 2 to 14 bar(g), and volume flow from 8 to 45 m³/min, is ideal where shore power is not available. This compressor can additionally be equipped with a generator, enabling it to function as an autonomous compressed air station. This is particularly beneficial when a compressed air dryer is required when the bubble curtain needs to be operated with dry air.

Both of these options are ideal for use in combination with bubble curtains, as they only compress the air to the pressure that is needed to overcome the hydrostatic pressure, as well as the losses of the pipe network. As every 1 bar(g) of overcompression increases the energy demand by 7%, savings of up to 30% are possible with both KAESER’s low-pressure electric stationary compressors, and low-pressure diesel portable compressor.

Are you interested to see what your savings potential might be? Contact KAESER’s compressed air aquaculture experts today to calculate your savings potential, and discover the optimal solution to energy-efficiently meet the compressed air requirements of your bubble curtain.

No, it will depend on the site conditions, ocean topography and many other factors. In some cases the better option may be an upwelling system, or even the combination of both.

KAESER works with expert companies worldwide who specialise in designing and installing bubble curtains and upwelling systems. We would be pleased to provide you with a list of our partners in your region. Contact us today!

Air is always taking the path of least resistance. There could be a number of reasons why areas of your bubble curtain are not producing bubbles, such as:

- your diffuser hose could be unevenly distributed,

- the length of the diffuser segments may be too long,

- the compressed air demand could be higher than the capacity of the compressor,

- if larger segments are out of air, the distribution panel might be incorrectly adjusted.

We would recommend that you contact your bubble curtain system provider to fully assess and diagnose the issue.