Compressed air applications in Aquaculture

Airlift collection systems

Fish mortalities (morts) are a natural occurrence in both wild ecosystems and aquaculture environments. Compared to mammals, fish produce high amounts of offspring (mostly eggs) with a comparatively low quality. This means that in wild ecosystems around 1% of offspring will reach adulthood.

In aquaculture - especially salmon aquaculture - an 80% survival rate is common. That means around 20% are not strong enough to grow to adulthood, and it is part of the natural order that they will die over the grow out cycle. In wild ecosystems weaker fish are typically removed by predators before they succumb naturally due to their weakness. However, the predator-free environment of net pens means that the carcasses of these weaker fish that die can quickly become vectors of disease and infection for the remaining fish. Aquaculture farms therefore need to efficiently remove morts from net pens in order to protect the well-being of the healthy fish, and thereby minimise further losses.

Airlift collection systems provide a safe, efficient and effective method of morts removal, which ensures morts are not left in net pens for extended periods of time, thereby keeping mortalities low. Compressed air is instrumental to the operation of airlift collection systems, facilitating the process of drawing up morts from the bottom of a net pen.

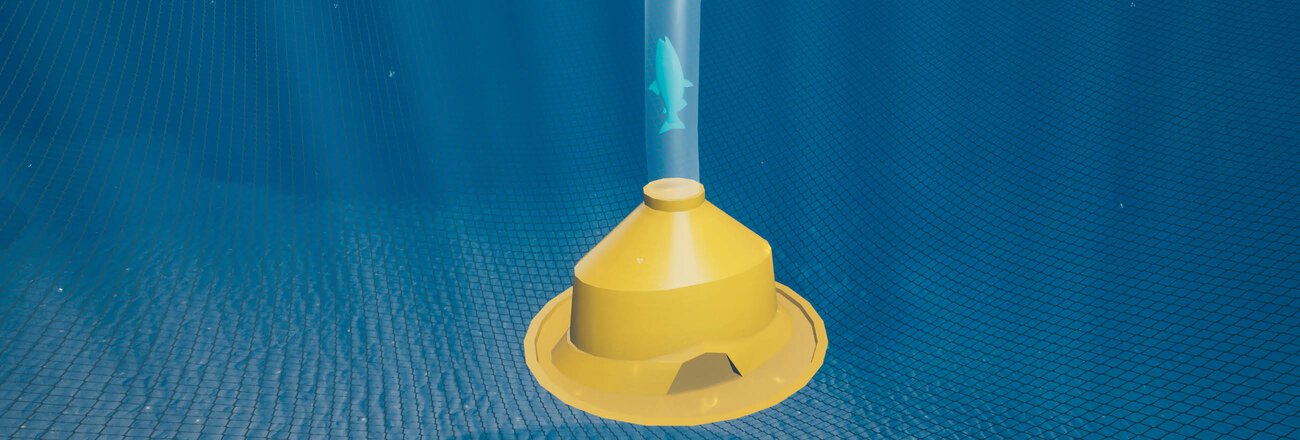

A cone device which is connected to a hose is installed in the deepest part of a net pen. Compressed air is then injected into the submerged hose. The compressed air reduces the density of the water inside the hose. This creates a mixture of air and water that is lighter than the surrounding water. This density difference causes the water in the hose to rise, lifting with it the morts from the bottom of the net pen to a centralised collection device on a support barge or boat for removal.

Aside from keeping mortalities low, frequent morts removal is also beneficial for accurate mortality reporting, as well as gaining knowledge about the standing biomass, so feed can be adjusted accordingly, resulting in less feed waste.

Increasingly important for sustainable aquaculture is reducing the environmental footprint. One of the challenges of open net pen aquaculture is that sea bed conditions can be negatively affected if the site doesn’t have enough current. This causes faeces to accumulate under a site. In the worst-case scenario, the biological load on the sea floor will exceed the habitat’s carrying capacity, resulting in habitat degradation. Recent airlift collection innovations are addressing these challenges, providing options to also collect sludge or faeces with the morts. Once collected, a band filter is used to separate the faeces or sludge from the morts, while reducing the water content. The thickened matter is then stored in a floating tank before being pumped into a boat that is then delivered to a biogas plant for gas production.

High compressed air quality is highly recommended for this application in order to protect marine life and ecosystems from contaminated water.

KAESER Solutions for Airlift Collection Systems

KAESER compressed air solutions are perfectly suited to meet the requirements of airlift collection systems, providing the reliable supply of compressed air necessary for the safe and efficient removal of morts.

Whether you require the compressor to be installed on your work boat, on your barge, or on the net pen itself, KAESER has a solution to meet your requirements. This includes:

- MOBILAIR portable compressors - compressed air whenever you need it, wherever you need it - even under the toughest offshore conditions. Featuring fuel-efficient engines or electric motor. Many models and options available with special enhancements for aquaculture.

- KAESER’s stationary rotary screw compressors - durable and high-performing compressors that deliver a reliable and efficient supply of quality compressed air.

- Specialist air treatment - a comprehensive range of compressed air treatment components to achieve the desired air quality.

KAESER custom-builds every aquaculture compressor to meet each customers specific requirements. Contact us today for expert advice.